Lithium Analysis: How Testing Supports a Circular Economy

What is lithium analysis, and why is it important?

From toddlers’ toys to festive fairy lights and the latest smart devices, lithium plays a major role in the products that shape the holiday season. Quietly, lithium analysis helps ensure materials meet quality standards at every stage, from extraction and processing to recycling and reuse.

As demand for lithium surges across sectors such as energy storage and electric mobility, reliable analysis is essential. It supports producers, processors, and recyclers in maintaining efficiency, product quality, and environmental responsibility throughout the lithium lifecycle.

How does lithium analysis support mining and extraction?

Global consumption of lithium has more than doubled since 2021, rising from around 95,000 tonnes to over 205,000 tonnes in 2024 (IEA). This has driven increased production in key regions such as Chile and Australia, alongside a greater focus on operational efficiency and environmental responsibility.

Global consumption of lithium has more than doubled since 2021, rising from around 95,000 tonnes to over 205,000 tonnes in 2024 (IEA). This has driven increased production in key regions such as Chile and Australia, alongside a greater focus on operational efficiency and environmental responsibility.

Lithium mining is a resource-intensive process. However, ongoing assessments of extraction and processing help reduce environmental impact. Through mineralogical and metallurgical analysis, operations can identify opportunities to improve recovery rates, minimise waste, and optimise processing methods.

At mine sites, laboratory analysis provides vital insight into ore quality, allowing rapid, data-driven decisions. By understanding the mineral composition and behaviour of lithium-bearing ores, producers can enhance yield while supporting sustainable practices.

Why is lithium testing critical for refining and trade?

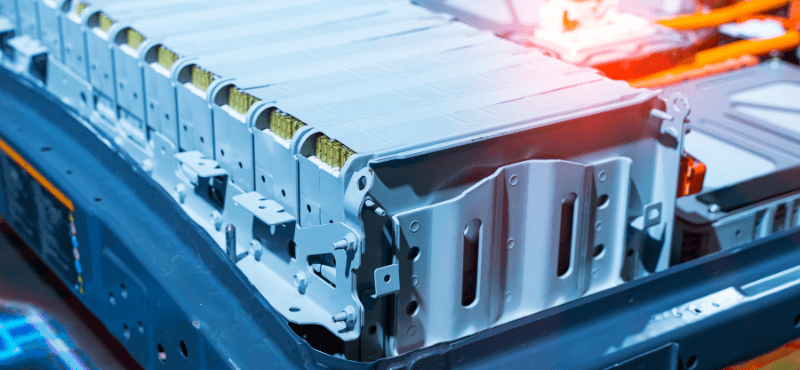

Once extracted, lithium is refined into compounds such as lithium carbonate and lithium hydroxide. These are used in battery manufacturing, glass, ceramics, and other industrial applications. The quality of these compounds, including impurity levels, concentration, and moisture content, directly affects their performance in downstream production.

Battery material analysis at refineries, warehouses, and ports ensures materials meet trade specifications and maintain consistency across the supply chain. Testing at this stage underpins operational efficiency and market integrity, giving producers and buyers confidence in the materials being traded.

Accurate analysis also ensures that the products reaching consumers are safe. From energy storage systems to the electronic gifts and gadgets exchanged each festive season, knowing that lithium materials meet specifications ensures both safety and performance

How does lithium analysis enable recycling and the circular economy?

By 2030, around 1.2 million tonnes of lithium-ion batteries are expected to reach the end of life. Recovering lithium from these products reduces reliance on primary extraction and supports a more sustainable, circular economy lithium model.

By 2030, around 1.2 million tonnes of lithium-ion batteries are expected to reach the end of life. Recovering lithium from these products reduces reliance on primary extraction and supports a more sustainable, circular economy lithium model.

Recycling lithium-ion batteries is complex. Black mass, the shredded material resulting from end-of-life batteries, contains lithium alongside cobalt, nickel, and manganese. Accurate lithium testing and material characterisation are essential to optimise recovery, verify content, and safely reintroduce these metals into the supply chain.

With AHK’s research and analytical expertise, the industry is developing better methods to recover valuable metals, remove contaminants, and refine black mass extraction. Analysis ensures that recovered lithium and other metals can be efficiently reused, closing the loop from extraction to recycling.

Driving a More Sustainable Lithium Future

Lithium analysis supports a circular economy by ensuring quality, efficiency, and sustainability across mining, refining, and recycling stages. Through accurate testing and continual innovation, the global lithium industry can operate more efficiently, transparently, and responsibly, supporting a truly circular approach to resource management.

From the mines of Chile to the batteries powering festive lights, lithium continues to shape the products defining modern life. Whatever your role in the lithium supply chain, speak to our experts to learn more about how lithium analysis supports quality, reliability, and sustainability across the full lifecycle.