From Rock to Revenue: The Power of Mineral Processing

In today’s mining landscape, ore grades are in decline and sustainability expectations are rising. As a miner or mineral processor, it is no longer enough to simply extract ore; you need to extract maximum value.

From understanding the unique makeup of your ore to designing the most efficient extraction and refining strategy, mineral processing is a crucial step between mining and trade, helping turn geology into revenue.

Could optimising your mineral processing operations be the difference between being marginal and profitable?

WHAT IS MINERAL PROCESSING AND WHY IS IT CRITICAL TO ORE VALUE?

Mineral processing, or beneficiation, is the separation of valuable minerals from waste rock. It transforms raw, heterogeneous mined material into a concentrated, marketable product..

By utilising various mineralogical, metallurgical, and analytical techniques – including physical processes like crushing, grinding, and screening, and chemical separation methods such as flotation and leaching – minerals are effectively prepared for further extraction of metals or direct use in various industries.

Effective mineral processing maximises mineral grade and recovery, minimises waste, optimises operational efficiency, and ultimately boosts profitability.

UNDERSTANDING YOUR ORE

The success of any mineral processing strategy starts with a deep understanding of your ore.

The success of any mineral processing strategy starts with a deep understanding of your ore.

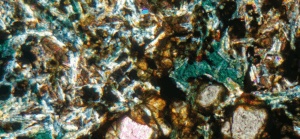

Mineralogical analysis reveals the makeup of your material: what minerals are present, how they’re distributed, how fine they are, and how they’re locked together. This information is fundamental to designing an efficient flowsheet. Without it, you’re relying on guesswork, often at the cost of recovery, reagent efficiency, and plant stability.

A robust mineralogical profile helps operators identify processing challenges early, tailor grind sizes for effective liberation, and avoid downstream inefficiencies that could impact metal yield.

Before you make processing decisions, make sure you know exactly what you’re dealing with.

GETTING THE GRIND RIGHT

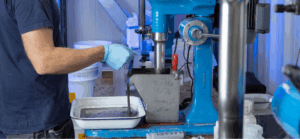

Crushing and grinding, known together as comminution, may seem like basic steps in the flowsheet, but they carry significant weight. In fact, comminution typically accounts for the largest share of energy use in mineral processing.

Crushing and grinding, known together as comminution, may seem like basic steps in the flowsheet, but they carry significant weight. In fact, comminution typically accounts for the largest share of energy use in mineral processing.

More importantly, it’s the stage where valuable minerals are physically liberated from the gangue. If your ore isn’t ground to the right size, those minerals stay locked and unrecoverable, even with the best separation techniques downstream.

Optimising comminution isn’t just about energy savings. It’s about finding the sweet spot: fine enough to liberate, coarse enough to avoid overgrinding. That balance is different for every ore, which is why testing, modelling, and mineralogical input are so important.

EXTRACTION, NOT JUST RECOVERY

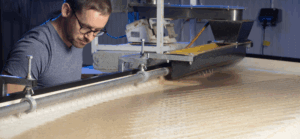

Once your minerals are liberated, the focus shifts to separation, the crucial step that transforms liberated particles into a saleable product.

Once your minerals are liberated, the focus shifts to separation, the crucial step that transforms liberated particles into a saleable product.

Depending on your ore, this might involve flotation, leaching, gravity separation, magnetic separation, or a combination of techniques. Each has its own operating parameters, and success depends on careful alignment with your ore’s mineralogy and chemistry.

While recovery rates often steal the spotlight, real value lies in designing a separation strategy that suits your material. That means optimising reagent selection, pH, residence time, and process sequence to suit your ore’s behaviour, not a generic flowsheet.

Bench-scale and pilot testing help define these parameters, guiding you toward a process that’s not just technically sound, but commercially viable.

When separation is done right, even lower-grade ores can become valuable products.

TURNING DATA INTO STRATEGY

Technical data only becomes powerful when it informs decision-making.

Technical data only becomes powerful when it informs decision-making.

Therefore, by combining mineralogical analysis, test work, and process modelling, you gain more than numbers; you gain insight into how your ore behaves and what that means for project economics.

Strategic test programmes, from grindability to flotation kinetics to leach recovery curves, reveal the practical boundaries of your deposit and enable smarter decisions on plant design, capital spend, and risk mitigation.

For new projects, this integrated approach helps turn drill core into a commercial strategy, forming the backbone of scoping and feasibility studies. For operating sites, it can unlock improvements in throughput, recovery, or cost efficiency.

In short: turning data into strategy is how you move from promising resource to profitable operation, with confidence and clarity.

UNLOCKING ORE VALUE WITH EXPERT MINERAL PROCESSING SUPPORT

At Alfred H Knight, we work closely with clients to understand their unique challenges, providing tailored, data-driven support at every stage of the mineral processing journey, from mineralogical analysis and metallurgical test work to flowsheet development, plant optimisation, and trade.

Our team doesn’t just deliver results; we collaborate with you to interpret them, guide decision-making, and refine your approach based on real material behaviour and practical outcomes. It’s a consultative partnership designed to help you extract more from your ore, efficiently, sustainably, and with confidence.

Whether you need support on a new project or you’re looking to improve an existing plant, our services help you unlock the full value of your ore, sustainably and efficiently.

Want to learn more about how AHK supports mineral processing operations around the world? Get in touch with our team to discuss your project and explore what’s possible.